MOUNTING SYSTEM

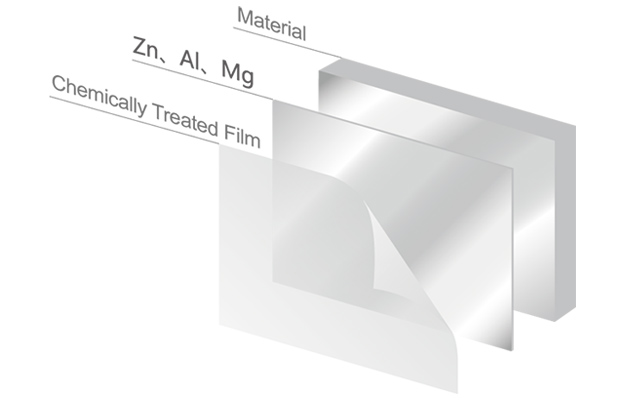

NEW MATERIAL

Magnesium-aluminum-zinc plated steel is coated with aluminum, magnesium, or other trace elements (silicon, nickel, etc.). The results show that the multi-alloy coated steel has excellent weatherability and comprehensive properties. It is currently used in many fields such as automobile, animal husbandry, and architecture. It is quite suitable to replace the traditional hot-dip zinc steel or GI plate in the field of PV mounting.

-

Strong Corrosion Resistance

-

Lower Total Cost

-

Environment Friendly

-

Excellent Appearance

-

Strong Self-repairability

-

Design and Optimization

Suitable for heavy corrosion application. The introduction of domestic top scientific research institutions technology, with repeated verification. The technology is widely applied in large-scale heavy-duty anti-corrosion projects in China, such as oil pipelines, bridges, sewage treatment plants, and so on.

· Super-strong corrosion resistance, suitable for heavy corrosion areas.

· Super adhesion of dryness and wetness/hardness/aging resistance and other comprehensive indicators.

· System-wide solutions (design/production/processing/repair/monitoring).

-

Long Service Life

In dry, less polluted areas, the corten steel PV mounting life can reach up to 30 years;

-

Maintenance-free

It doesn't need cumbersome maintenance, which will reduce operating costs.

-

Reduced Cost

Without hot galvanizing, the combined cost will be reduced by more than 15%.

-

Environmental Protection

It doesn’t need hot-dip galvanizing treatment, which leads to energy saving, environmental protection, and optimization of the delivery period.