The photovoltaic conversion efficiency is the most critical yardstick for each time when a new photovoltaic cell technology tries to iterate the old. As one of the most promising technology routes for next-generation photovoltaic crystalline silicon cells, cost reduction and efficiency enhancement of heterojunction (HJT) cell is highly concerned.

Since the start of 2023, a range of core improvements for cost reduction and efficiency enhancement of HJT cell have been achieved by Akcome Science and Technology (Akcome), a global leading HJT manufacturer, including thinner cell, surface microcrystallization, less silver paste, indium-free TCO, and perovskite-HJT tandem, etc., which continued to promote the improvement of HJT cell conversion efficiency.

From Single Side to Bifacial Microcrystallization

Compared to traditional amorphous silicon (A-Si) film, microcrystalline silicon film offers better performance including better light transmission, better fill factor, lower current, higher open-circuit voltage, and higher electric conductivity, and its application will improve the conversion efficiency of HJT cell by 0.2-0.3% or more.

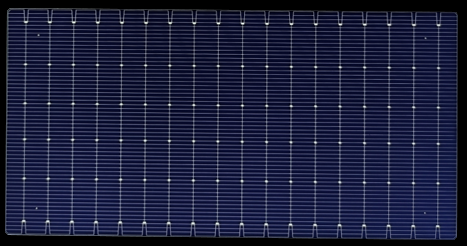

▲ Akcome 210-18BB bifacial microcrystalline HJT cell

Akcome's microcrystallization process is to form a microcrystalline silicon film on the surface of heterojunction cells by VHF–PECVD technology. Akcome has achieved an average conversion efficiency of mass production of single-sided microcrystalline HJT cells of 25.3%-25.4%, with a production yield of 98%. In the fourth quarter of 2023, Akcome will carry out mass production of bifacial microcrystalline HJT cells, and it is expected that the average conversion efficiency will reach 25.6%-25.7%, which is in a leading position in the industry. Meanwhile, Akcome has utilized light conversion film and double AR layer coating glass on module encapsulation and pushed the CTM to 98%, which has minimized the power loss of encapsulation from cell to module.

SMBB and 0BB

Akcome has developed technologies such as Super Multiple Bus Bar (SMBB) and Zero Bus Bar (0BB) to reduce cost and improve efficiency.

SMBB technology reduces the height and width of bus bar by increasing the number of them and improves the light utilization and reduces silver paste consumption and power loss. Starting from 2022, Akcome's shifted HJT module products from 12BB to 18BB. The highest power of the 210-66 model HJT module finger(18BB) has exceeded 720W, and the average power of mass production reaches 705W.

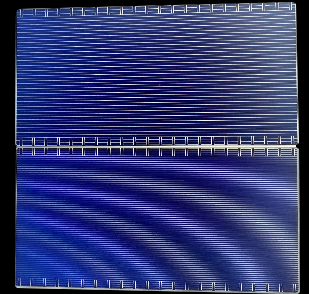

▲ Akcome 0BB HJT cell

Refer to 0BB technology, Akcome adopts copper welding tape to interconnect cells and collect current from finger, and there are no silver bus bars on both front and back sides of the cell. Besides, the fingers use silver-coated copper paste and reduce the overall silver consumption of the cell to less than 8mg per watt. Furthermore, the number of copper welding tape supported bus bars can be increased to 22-24 BB with utilization of low-temperature laminating technology. During SNEC 2023, Akcome launched its 0BB HJT module with power output of up to 730W and conversion efficiency to 23.5%. Akcome expects to mass produce 0BB HJT modules by the end of 2023 or the first half of 2024, and the cost of silver paste can be reduced to about CNY0.03-0.04/Watt.

Thinner Cell

HJT have natural advantages in adapting thinning treatment. Firstly, the thinning of HJT wafers will not significantly affect its efficiency. Compared with the thinning limit of 150um for traditional PERC cells, the thickness limit of HJT cells, which will rarely affect the conversion efficiency, is about 90um; secondly, HJT's production process is simple and in a low-temperature environment, which is not easy to produce wafer warping or even fragmentation.

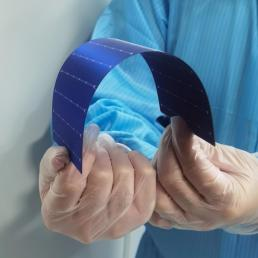

▲ Akcome 110um Thinner HJT Cell

Currently Akcome is pilot testing wafer with thickness of 110um, which can improve efficiency by more than 0.2% compared with 150um thickness and reduce cell cost by CNY0.03~0.04/Watt. According to the R&D planning, Akcome plans to use 100um wafers by the end of the year, and then go further to 90um in middle of 2024, which will help reduce the cost of its HJT cell to the same level as of current PERC cell.

Reducing Silver Consumption

Silver paste is the core auxiliary material for HJT cell production and accounts for more than 40% of non-silicon cost. Akcome continues to focus on silver-less technologies such as silver-coated copper and copper electroplating to reduce the cost of silver consumption. Today, Akcome uses silver-coated copper paste with silver content of 40% -50%, which with less cost than the industry's mainstream proportion of 50%. In future, silver-coated copper paste with silver content of 30% -20% is Akcome's target.

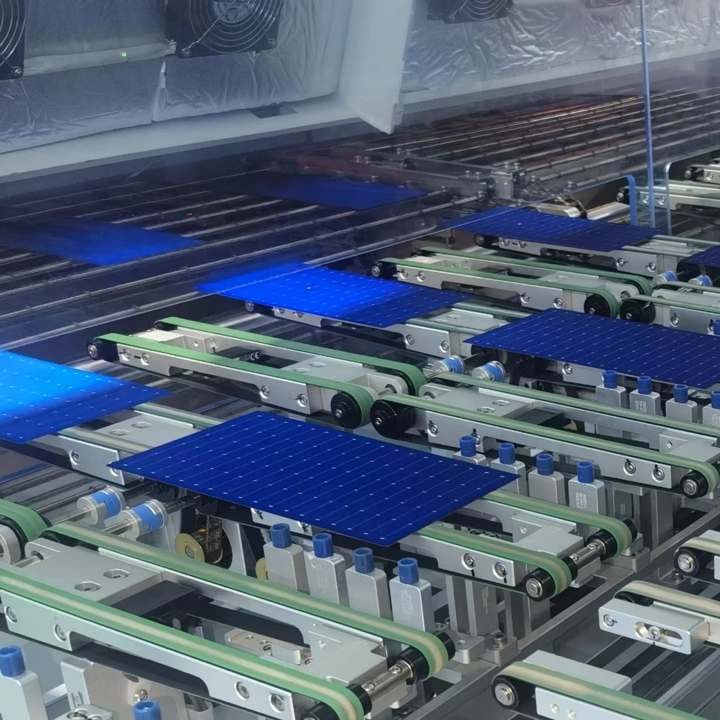

▲ Akcome HJT Cell Mass Production

Since 2018, Akcome has been developing copper electroplating technology. Currently, Akcome has built a pilot line for copper electroplating, and the module encapsulation process and module reliability are being tested. Bifacial microcrystalline HJT cells supported by electroplated copper metal bus bars will bring about 0.5% improvement in conversion efficiency.

Dr. Xiner Huang, Vice President of Akcome Technology Research Institute, introduced, “Akcome has achieved the goal of less silver in HJT through silver-coated copper, copper electroplating, bus bars graphic optimization, and 0BB, etc. It is expected that the cost of silver paste of HJT can be reduced to CNY0.05/Watt, by the end of 2023.”

Indium-free and Indium-reduced TCO

Indium, a rare metal in Indium Tin Oxide (ITO) targets, is a major factor in the high manufacturing cost of HJT cells. To reduce the metal cost, Akcome is continuously developing indium-free and indium-reduced Transparent Conductive Oxide (TCO) coating solutions. Currently, Akcome is steadily advancing the pilot line of indium-reduced and indium-free TCO, which is expected to be introduced into mass production in early 2024. With the introduction of indium-free TCO, the cost of TCO will be further reduced by CNY0.01-0.02/Watt.

Perovskite and HJT Tandem

Perovskite and HJT tandem cell are cutting-edge technology directions to enhance the potential of HJT technology. Akcome has set up a professional R&D team and focus on the research, preparation, and application of Perovskite-HJT tandem cell. Currently, Akcome is building a pilot line to see an initial goal of exceeding 30% average cell conversion efficiency.

Several Chinese research institutes believe that the efficiency lift of HJT cell is the key to its completion of technology substitution. Akcome expects that by the end of 2023, the cost of Akcome's HJT module is equal to that of TOPCon module, and it will take advantage over TOPCon with higher conversion efficiency and better performance characteristics.

As a global leader of HJT technology, Akcome has obtained 4GW HJT cell production capacity so far and seeking more in future. Akcome will take the lead in providing high-quality, high-efficiency and low-cost N-type HJT module products to global customers.

Answering Time: 8: 00-17: 00 on weekdays

HQ: 0571-89089399

Sales: +86-512 8255 7328

Mail: modulesales@akcome.com

Headquarters: Room 901, Building 1, No. 1818-2, Wenyi West Road, Yuhang Street, Yuhang District, Hangzhou City, Zhejiang Province